If you are thinking of cutting glass materials with a power saw, table saws might be the best option for you as they are versatile tools suitable for different cuts on various materials.

Though plexiglass is not a pure glass material, it is used instead of glass and can be cut on a table saw using the right blade and proper technique.

Cutting plexiglass with a table saw might seem difficult as glass materials can crack down very easily during the cutting process. But if you know how to cut plexiglass on a table saw, things will get more straightforward. Some easy procedures can help you through this.

We are here to provide you with all the guidelines and methods that will be essential for you to cut plexiglass on a table saw.

In this post we'll cover:

Types of Plexiglass Sheets

Plexiglass is a type of clear acrylic or plastic that is see-through and can be used as an alternative to glass. They are popular among people for being less fragile than glass. Generally, you will find three types of plexiglass sheets-

1. Cast Acrylic Sheets

Among the three types of plexiglasses, these sheets are costlier and the most used. Properly cutting them is truly difficult as they are hard to break. But you can cut them with a table saw like some of these even without melting them.

2. Extruded Acrylic Sheets

These are softer than cast acrylic sheets, and thus they can be molded into different shapes. Because of such texture, their melting temperature is low, and we can’t cut them using electric saws.

3. Polycarbonate Sheets

The melting temperature of polycarbonate sheets is somewhere between the cast acrylic sheets and extruded acrylic sheets.

They are not as soft as the extruded acrylic sheets but yet not too hard. You can cut them by using power saws, but the process is complicated and needs extra caution.

Cutting Plexiglass on a Table Saw

You need to consider some minor details and the proper method while cutting glass on a table saw. Because these ensure the accuracy of cuts as well as enable you to remain safe during the cutting process.

A complete guideline is discussed here for a clear understanding of cutting plexiglass so that you can master it after a few practice sessions.

Things to Consider

Before starting the cutting procedure, some initial measures should be taken and considered an essential part of the whole procedure.

1. Using Necessary Safety Gears

Power saws are often accident-prone, and you might have mild to severe injuries without having the essential safety gears. The must-have things are; hand gloves and safety glass. You can also use an apron, face shield, protective shoes, and other things that might be helpful.

2. Choosing the Right Blade

One particular blade doesn’t fit for every cut and every material. When you are cutting softer plexiglass, use blades with a smaller number of teeth so that the glass doesn’t melt during the process. For hard plexiglass, blades with more teeth are great as they prevent cracking the glass. Also, sharpen table saw blades if they’re not sharp enough before starting the operation.

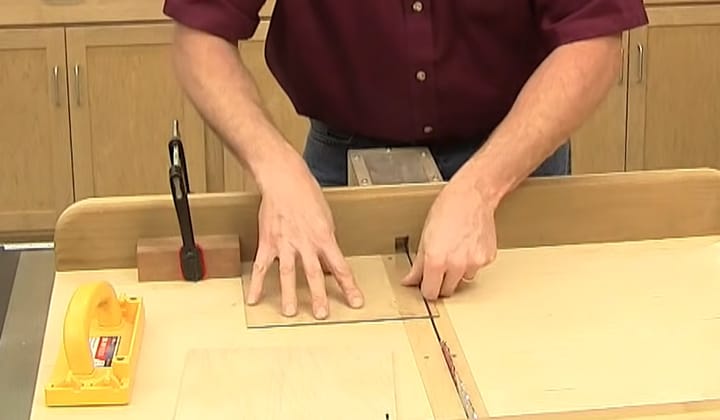

3. Measuring and Marking

For a perfect cut on your plexiglass, accurate measuring is necessary. Take measurements of the cut and mark them on the glass. This will enable you to run the blade according to the mark and ensure a precise cut.

4. Estimating the Thickness

If you are about to cut a thin plexiglass sheet, you need to be careful as a table saw can’t cut plexiglass sheets less than ¼ inch thick because thinner sheets have a low melting temperature and might melt during cutting with a power saw.

Besides, thinner glass sheets need more pressure while sliding through the blade as they stick to the fence or clamp tightly.

5. Adjusting the Feed Rate

Compared to any other material cutting on a table saw, plexiglass needs a lower feed rate as they are fragile and can break anytime if the speed is high. There is no proper adjustment in a table saw to set an exact feed rate. Just make sure the sheet doesn’t go more than 3 inches/second.

Procedures

The following step-by-step procedures will make things easy for you while cutting plexiglass sheets with a table saw.

- Choose a blade according to the plexiglass type and set it up by adjusting the necessary blade tension. Tighten the blade properly but not too tight as it might crack down due to excessive strain.

- Keep a small distance between the glass sheet and the blade to maintain the accuracy of the cut. The standard distance is ½ inches.

- It is better to make a mark for an easy cutting process. Mark on the glass according to your measurement of the cut.

- You will find most of the plexiglass has a protective shield on the surface. Please don’t remove this protection while cutting, as it prevents the tiny glass pieces from scattering over the whole area. Besides, it also prevents scratches on the glass sheet surface.

- Keep the glass along with a fence. If your table saw doesn’t have a fence, use a clamp instead. It will prevent the glass from moving.

- Place the glass sheet under the blade while keeping the protective shield facing downwards.

- Now, turn on the power to run the blade of your table saw. Don’t start cutting unless the blade reaches the maximum speed. You can also adjust the speed according to the type of cuts.

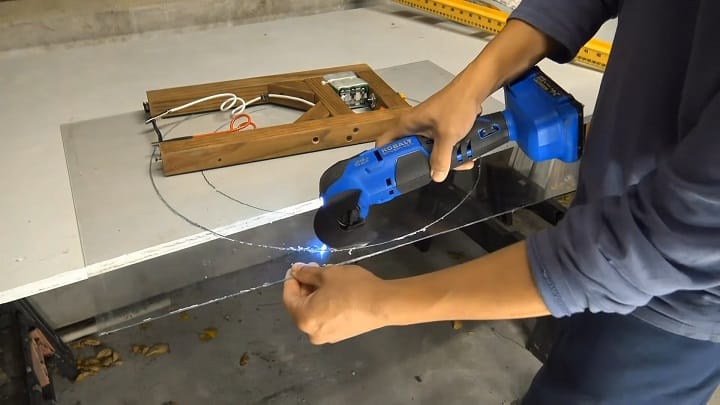

- While cutting curve lines or circles, take clean turns to avoid rough and uneven edges. Go slower and don’t start and stop repeatedly. But in the case of straight cuts, you need a higher speed compared to curve cuts.

- Push the glass piece with a push stick instead of using your hand. Otherwise, any accident might occur if you don’t maintain a safe distance from the blade.

- Finally, after you have cut the plexiglass sheet, sand the uneven edges with sandpaper.

Final Words

There are versatile uses for table saws. Though plexiglass is a sensitive material for cutting and shaping, a table saw is relatively easier to use while cutting these glass sheets. We hope you will master how to cut plexiglass on a table saw after a few attempts.

I'm Joost Nusselder, the founder of Tools Doctor, content marketer, and dad. I love trying out new equipment, and together with my team I've been creating in-depth blog articles since 2016 to help loyal readers with tools & crafting tips.